C-SHELL & C-FIBER

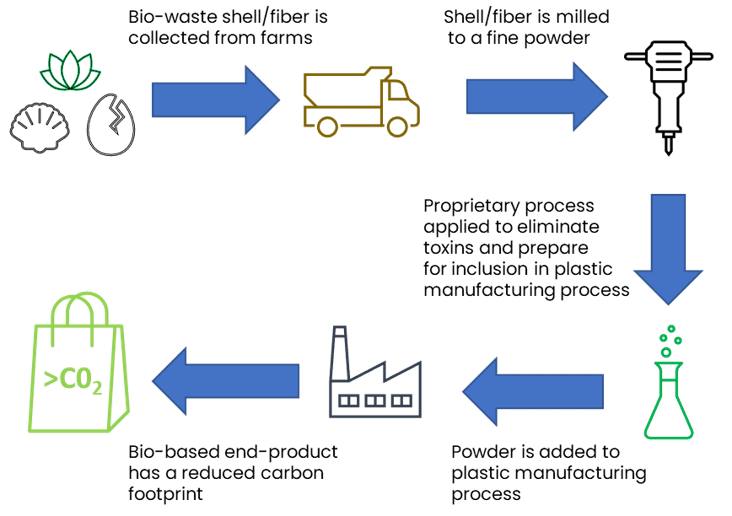

We recycle bio-waste in the form of discarded eggshells, seashells and crop fibers to create our 100% bio-based plastic and rubber substitutes, thereby reducing the environmental impact of the end-use product

C-Shell is sourced from discarded eggshells and seashells while C-Fiber is sourced from crop waste materials (such as agave and hemp). When added to the plastic (or rubber) manufacturing process, they can reduce the carbon footprint by up to 80%.

What’s more, both C-Shell and C-Fiber are cheaper and less price-volatile than oil and enhance the performance properties of the end-product.

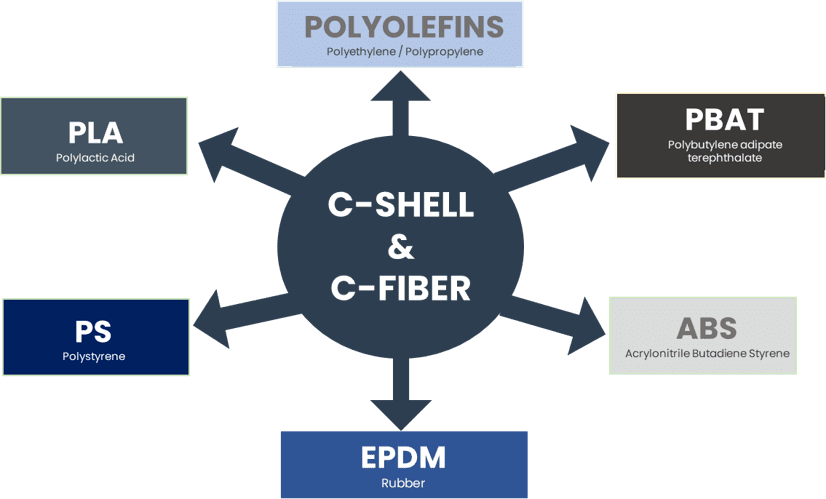

Both C-Shell and C-Fiber are compatible with a wide range of plastic products.

Bio-Cycle

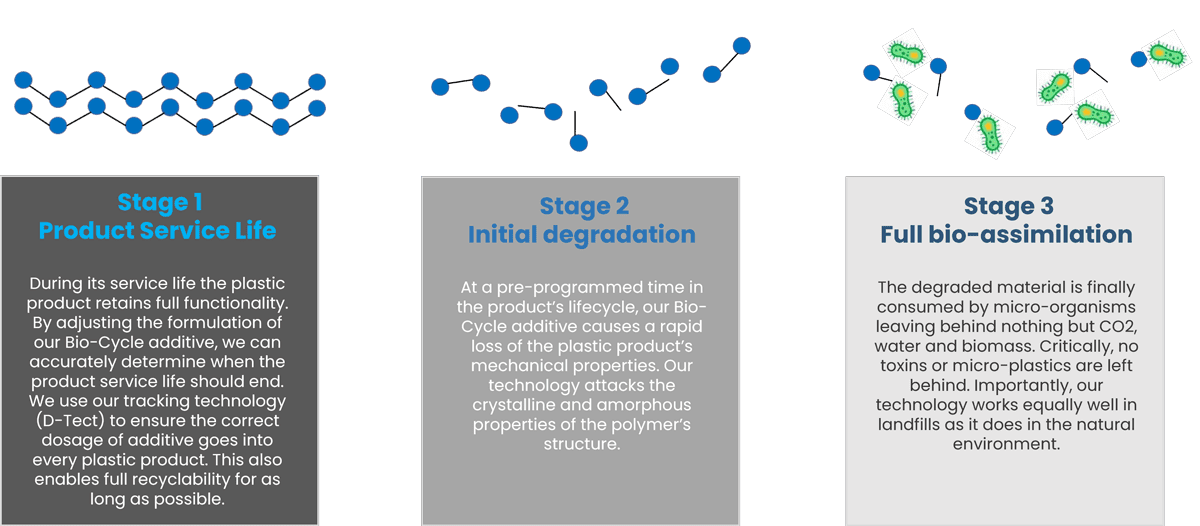

Our Bio-Cycle additive allows the plastic to safely bio-degrade at the end of its natural life (even after several rounds of recycling).

Bio-Cycle breaks down the plastic at the molecular level creating a food source for microorganisms. Once the microorganisms have finished their meal, no toxins or microplastics are left behind - just biomass, water, and CO2.

Bio-Cycle works effectively on plastic litter in the sea and on the land, as well as in landfills.

Our Bio-Cycle formulation can be adjusted to cater to the planned service life of a particular product - this is typically between 12 and 24 months. During such a period, powerful stabilizers prevent our additive from breaking down the plastic’s mechanical properties.

Performance Additives range

Planet Polymers has an additional range of additives that further enhance the performance and properties of a wide range of plastic products. They offer significant health benefits, reduce food waste and offer a better customer experience.

Anti-microbial

Anti-fungal

Odour-eliminator